Oil Fired Steam on the Welsh Narrow Gauge

Shaun McMahon describes in detail, with the reasons, the conversion of Welsh narrow gauge steam locos from coal firing to an oil firing system now extensively used by a number of railways.

"Where do you keep the coal then Mister?"

The number of times that the writer has been asked this question while driving trains at the Vale of Rheidol and Ffestiniog Railways is uncountable. The reply of 'we don't carry coal sir, as it's an oil fired steam locomotive,' is normally followed by a long explanation into the reason behind the conversion to burn oil and how the system works, not to mention reassuring the by-now distressed passenger that he or she is still travelling behind a proper steam engine.

Oil-fired

steam engines have been in existence for many years in Britain, not to mention

overseas countries. The Great Eastern used oil firing nearly a century ago and

in the 1940s the Great Western converted a number of its fleet to burn heavy

fuel oil, the primary motive of

that exercise being to overcome the acute coal shortage suffered at the time.

Initially the GWR hoped to save some 13,000 tons of coal by the conversion of

18 locos to burn oil.

However, it was only in the late 1960s that the now world-famous Ffestiniog Railway looked seriously into the possibility of adopting such a system.

Following the reopening of this line, train capacity had been steadily increasing over a number of seasons. Naturally under these conditions, locomotives were worked harder, thus increasing the amount of carryover from the firebed. As the railway now ran through dense woodlands for a number of miles, the result was disastrous, with forest fires becoming almost a daily hazard. As the fire risk increased, so did the railway's annual insurance premium. Something had to be done to eliminate the problem, the natural course of action being to adopt a method of combustion that didn't involve the risk of spark emission and also provided efficient combustion under arduous operating conditions.

|

Textbook

oil firing. Vale of Rheidol's No 9 Prince of Wales approaches Rheidol

Falls on a warm August day in 1991. The chimney is emitting a 'grey haze',

showing that almost perfect combustion of the gas oil is being achieved.

© John R. Jones |

Conversion to oil firing looked like an obvious answer and after much investigation it was decided by the company to adopt the Laidlaw Drew system of burning oil.

The method of combustion is fairly straightforward. Fuel oil is fed by gravity from a tank (placed in the locomotive's former coal bunker or tender) through a pipe directly to the swirl burner. Steam is also fed to the burner via a separate pipe. The steam is fed annularly via a swirler while the oil is fed directly through the centre of the burner until it reaches five equispaced radial holes in the burner's film-screw body. The oil is emitted through a gap nominally 0.025in for gas oil, though the gap is, often enlarged when attempting to burn heavier grade fuel oils.

The swirling steam effectively 'catches' the fuel as it exits from the burner and in turn atomises it within the firebox. Emission between the burner choke and angled film-screw cap decides the final flame form in relation to firebox grate area, volume and forced draught. The conventional grate is replaced by a fire panplate, which contains air tubes angled at 29° to the horizontal and forming a circular path of primary air, in order to encourage good combustion.

In this particular system the amount of primary air cannot be controlled. Following ,some very recent tests carried out by the writer, it is evident that the system would benefit from some form of controllable damper system, in order to limit the degree of primary air entry via the pan plates as required under different steaming conditions.

Refractory brick is cast onto the lower walls of the firebox and panplate. A brick arch of optimum length and angle is also employed in order to distribute evenly the flame over the tube bank and provide some degree of protection for the tube and superheater element ends. The flow of oil to the burner is controlled by a graduated oil valve. Atomising steam is fed via a separate valve. The mixing ratio of fuel to steam is in the main empirical and varies in relation to firebox volume, fuel viscosity and even the temperament of the fireman!

Firing is usually carried out according to the chimney's emission, which normally gives a good indication of combustion quality. When firing on gas oil, a grey haze is adequate to provide good steaming, while a few can-falls of sand poured down the inspection port when on the move is enough to keep the tubes and superheater flues free of soot formation. On heavier oils though, slightly more smoke has to be made and manual sweeping of the tubes is required.

A forced draught is needed for combustion for all but the very lowest of oil settings, as steam is used for the blower and atomisation of the fuel, raising steam in the morning in the absence of boiler pressure would seem to pose somewhat of a problem. To overcome it, compressed air is fed in via a pipeline as a steam substitute, the airline being connected to the auxiliary manifold, while the steam side of the circuit is kept closed. Changeover to steam occurs when sufficient boiler pressure has been raised to supply both blower and atomiser, nominally 50psi.

As one would imagine, unlike the gentle warmth that is given off from a coal fire during the early stages of lighting up, the oil Fire's relatively high temperature is instantaneous and great care has to be taken by the crews not to raise steam too rapidly. Reasonably rapid heating on a steel firebox is not too unhealthy; however the effects on a copper box can be disastrous, taking into consideration dissimilar expansion and contraction rates of, say, copper tubeplate and steel tubes!

As you would expect, perfection of the system did not happen overnight. Indeed it took a number of years of development to achieve the desired results.

Linda was the first of the FR fleet to undergo conversion, the equipment being fitted in the autumn of 1970, having been ordered from Laidlaw Drew of Edinburgh some time earlier. At the time, Linda was the regular engine of the then General Manager & Engineer Allan Garraway and was therefore an ideal test-bed for trial running. Also the late Paul Dukes was Works Manager at Boston Lodge, with Paul Harris as his assistant, and between them they painstakingly attempted to perfect the new equipment that had been supplied.

|

The

prototype. A newly-converted Linda at Harbour station, Ffestiniog Railway,

in 1971. One teething problem was the high smoke box temperature burning

off the paint. Aluminium primer was the aesthetically horrible solution

until a suitably heat-resistant black paint was identified. © Dan

Wilson |

Preliminary trials were carried out in the presence of representatives from Laidlaw Drew and were, to say the least, very disappointing. Steam production was poor and various adjustments carried out were to little avail. The burner manufacturers had, maybe, not realised how great the required steaming rate had to he.

Testing continued over a period of several weeks and during this time several modifications and improvements were carried out to both loco and equipment. The efforts of the Works' ingenious team paid off when, in the presence of Mr Patterson of Laidlaw Drew, Linda handled the Christmas train with hardly any difficulty.

Techniques in method of design and operation still had to be improved on. However, by the time of Blanche's conversion in the spring of 1971, much experience had been gained and a number of rule-of-thumb formulæ evolved.

In Blanche, Boston Lodge's own type of modified equipment and control gear, along with new fuel tanks and four-piece flexible brick arch, were all incorporated from the very start. Unlike her sister, Blanche was in poorer mechanical condition and unsuperheated. Nevertheless, after a few weeks' testing, the FR had two members of its fleet running trouble free as oil burners.

At the end of the 1971 season the Alco Mountaineer was brought into works for similar treatment. Drastic rear end surgery, had to be carried out, in order not only to fit the new equipment but also to improve the steaming and overall economy of the loco.

The Alco had never performed well as a coal-fired unit. After a period of trial running on oil, it had reached a standard of performance well in excess of anything achieved with coal tiring.

The next FR conversion was probably the most challenging of all - a double Fairlie, namely Merddin Emrys. Construction of the new Earl of Merioneth was already under way and its design incorporated oil firing equipment and auxiliaries. However, as Merddin was in service, it was decided to convert that loco first, to give a reliable testbed; thus, if any modifications were found necessary, they could be incorporated in Earl's design from the outset.

The Fairlie worked its last coal-fired train in October 1972 and conversion work was carried out over that winter.

Now a double engine boiler, under normal operating conditions, does not have to steam at a rate equivalent to two single boilers, even though it has just over twice the theoretical capacity. Hence, making a double engine steam did not present a problem; however, making it accept the equipment was quite a different matter. In the words of Bob Harris, 'the space problem isn't just doubled - it's cubed!' However, once again the engineering team at Boston Lodge proved that they could overcome these inherent problems and Merddin Emrys entered service as an oil burner in 1973. The new Earl of Merioneth was duly completed in 1979, and Prince followed in 1980 after a major rebuild.

The Ffestiniog experience was being watched with interest from elsewhere and not surprisingly there were some followers. During the early 1970s, for a number of reasons (ease of operation, coal quality etc), the Snowdon Mountain Railway decided to convert a part of its steam loco fleet from coal to oil firing.

This conversion was not particularly successful. Unlike the FR, which had chosen a swirl burner of 1 3/4 in choke diameter, the Snowdon opted for 2 in diameter. Though this may not seem a great difference, the increase in combustion rate proportional to firebox volume is vast and much trouble was experienced in this particular field. The SMR locos were reconverted to burn coal after a period of trial running.

During the mid 1970s the Vale of Rheidol Railway was beginning to suffer problems with its coal-burning fleet similar to those faced by the FR a few years previously. The line climbs some 680ft on its 11 3/4 mile run from Aberystwyth to Devils Bridge, with the gradient on the last 4 1/2 miles a steady 1 in 50 through dense woodland. As with the FR in the 1960s, forest fires were becoming a daily hazard and insurance premiums were rising steadily! Indeed, during the long, hot summer of 1976, many service trains on the line were cancelled due to this very problem!

British Rail, then owners of the line, referred to the FR for expert advice and it was decided that the fleet of Swindon-built 2-6-2Ts would be converted to burn oil, with the Ffestiniog carrying out the work for BR.

The first subject was No. 7 Owain Glyndwr and Boston Lodge set about manufacturing a suitable panplate and ordering the necessary equipment. It was also decided to use the same size burner as on FR locos (1 3/4in choke diameter) although the firebox volume on these locos is much greater than on any FR engine. For instance, Prince has a firebox volume of 13.37 cu ft, a double engine 24 cu ft, while on a VoR loco it is 35 cu ft! However, unlike FR locos, which are worked very hard in relation to their size in order to haul heavy trains on a gradient of 1 in 80, the VoR locos spend most of their time at part load, therefore not needing such a rapid rate of steam production. However, when worked hard the VoR locos do steam very well indeed with this size of burner and judicious use of atomisation provides adequate distribution of the flame to all corners of the box.

Work was far enough advanced for the new equipment to be fitted at Aberystwyth Shed during the 1977/78 winter and Easter 1978 saw the first oil-fired VoR steam loco haul a passenger train to Devils Bridge.

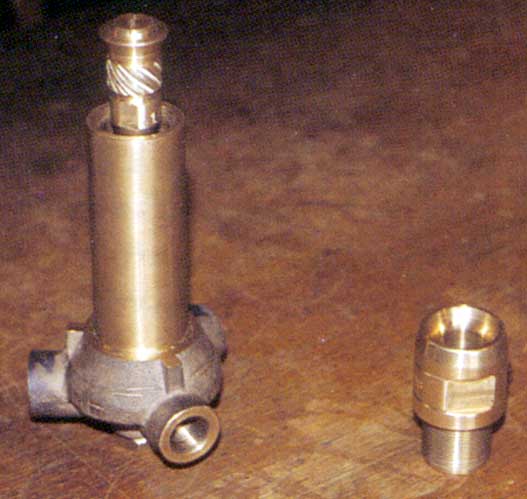

|

The

heart of the beast. A burner unit removed for attention from a VoR loco.

Note, apart from evident work erosion, the baseplate with steam holes,

the swirl vanes above and the oil column centre. © Shaun McMahon |

In those days loco crews on this line, as part of the BR roster, worked main line trains out of Aberystwyth as well as their occasional shifts on the narrow gauge. A certain amount of familiarisation with the newly-installed equipment had to take place before many of the older hands accepted it as a good thing!

Initially the FR was responsible for training personnel both to operate and maintain the equipment. As fitters and crews became familiar with the equipment, the VoR was able to become more or less self-sufficient in this respect.

The conversion of No. 8 Llewelyn took place in time for the 1979 season and No. 9 Prince of Wales followed in 1981. Fuel oil on the VoR locos is carried in tanks placed inside the old coal bunkers. Incidentally, during the Snowdon's 1970s experiments, the fuel was carried in tanks fitted to the cab roofs. This may seem a little strange a first glance but it provided sufficient head for the fuel to reach the burner by gravity when the loco was running nose-up on the very steep grades.

The VoR has used neat gas oil as fuel from the outset of the conversion programme, it being the fluid equivalent of Welsh Steam Coal. However, this has not been the case on the FR.

During the oil crises of the early 1970s, prices rose drastically and to crippling levels. By the mid-1970s, in an attempt to counter this, some very serious thought was given to burning waste oil as an alternative to gas oil. Experiments went ahead quite successfully. Waste oil was collected by society members, car sump oil being a favourite as it generally came free of charge. As time went by the proportion of waste oil burned steadily increased, though it was 'spiked' with gas oil before use.

Smoke emission and combustion deposits rose dramatically and by 1980 daily tube cleaning by brush as well as sand became normal practice. Scraping firebox walls to remove deposits and allow optimum heat transfer became more frequent. It was also at this time that tube sanding on double engines was prohibited, as most of the sand remained in the firebox - as access to the firebox is on the side wall of a double Fairlie boiler, the sand did not fall into an area of sufficient gas movement to get drawn into the tubes at the required velocity.

In October 1979 a heating coil was fitted to Linda's fuel tank, taking steam from the oil firing manifold drain valve, to pre-heat the fuel before it passed to the burner. This system worked well for a number of years and was fitted to the tanks of other locos in the fleet.

Another problem of burning waste oil was frequent blockage of the burner, so primary filters were fitted to the fuel line to catch deposits, though on several occasions these were not enough to absolutely prevent the carryover of unwanted matter that would block the precision-sized burner.

However, burning waste oil did have a positive effect on the fuel bill, cutting several thousand pounds per year.

One problem suffered after the conversion was the corrosion and cracking of superheater elements, particularly on the return bends. After much experimenting the solution found and adopted was to use 361 grade stainless steel bends.

The viscosity of waste oil varies from 28sec to over 3,000sec, so before use it was mixed with proprietary oils to achieve a uniform viscosity of about 120sec. A centrifuge was installed for use to remove solids. The most economic ratio of waste to propriety is in the region of 3:1 but to achieve this needed more waste oil than FR volunteers and members could provide. During the early 1980s fuel costs were around £50,000pa and a great deal of research was carried out into ways and means of trimming the bill. In-service flue gas analysis was used as a guide to improving combustion.

At the same time a great deal of work was done on developing the gas-producer combustion system of coal firing to suit FR locos. This particular system is the only coal firing method to rival oil firing and was successfully tested on Linda during 1985-6. The fall in oil prices at the time led to the loco being re-converted to oil. It is interesting to note that conversion between the two systems took only a few days.

With the introduction of COSHH Regulations, the burning of waste oil has had to be carefully reconsidered by the FR and as a result the Railway has been burning black (dirty) gas oil and some neat gas oil as an alternative to waste, though collection of waste oil continues as part of a deal to reduce the cost of purchasing black gas oil! At the time of writing, neat gas oil is being burnt in FR locos.

Meanwhile, the now-privatised VoR's parent company the Brecon Mountain Railway had been looking seriously at oil firing for a number of years. Not only could it prevent the risk of forest fires once the line is extended beyond Pontsticill but it would also reduce labour costs. Neither the VoR nor the BMR use volunteers, only a small corps of skilled, flexible staff, all able to turn their hands to most tasks. Therefore any system that involves hidden labour costs is regarded with some reservation.

|

The

new centre column of the Laidlaw Drew burner for the BMR's Arn Jung loco.

© Shaun McMahon |

At the end of 1992 the BMR's Arn Jung 0-6-2WTT Graf Schwerin-Lowitz became due for boiler replacement, which gave an ideal chance to convert the loco from coal to oil firing.

A design had been drawn up as far back as 1975, once again on the Laidlaw Drew system. To overcome problems of inaccessibility due to the rear pony truck, a split panplate was designed and fitted. The burner is smaller than those used on the VoR and FR, the firebox volume on this loco being only 11 cu ft. Choke diameter is 1in (Laidlaw Drew swirl burners being available in 1/4 in choke diameter increments). The loco re-entered traffic in April 1993 and after a few teething troubles were cured the loco has performed satisfactorily in service. The BMR also plans to outshop its ex-South African Railways 2-6-2+2-6-2 Garratt and Baldwin Pacific as oil burners in due course, although it is probable that burner diameters of around 2 in and 1 1/2 in will be needed.

|

Firebox

ancillaries for the Arn Jung; the pan plate sections, showing the angled

air intakes and the refractory infilling, and the firebox door backing

plate.© Shaun McMahon |

Moving the story back to North Wales, in order to counter the lack of availability of good quality coal, the Snowdon Mountain Railway is once again looking at the possibility of converting its fleet to burn oil.

The new equipment has been fitted to No 2 Enid, also the recipient of a new, all-welded boiler. The SMR has recruited former East African Railways engineer Eric Cowley to supervise the development of the system.

Unlike the other railways covered in this report, the SMR has opted for a design which includes a 'Mexican trough' flat burner. It was hoped that once trials were completed the loco would enter service during the 1993 season but in the event the experimental stage was not completed by the end of the season and developments to bring the system to a satisfactory level of reliability was still in progress.

What of the future?

Well, the Swiss Locomotive and Machineworks has recently completed a small batch of oil fired rack steam locomotives. To counter problems suffered with other systems, designer Roger Waller went back to the drawing board and developed a totally new oil firing system. Four main, vertically fired, burners are employed and a pilot burner is also fitted for idling and shunting duties. No refractory brick is required with this system and the arch is manufactured from stainless steel sheets. The atomising steam for the burners is superheated, thus reducing the wetness fraction and bringing it nearer to the state of a perfect working gas, a 10% fuel economy is also achieved with superheated atomisation.

The oil flow and steam atomisation valves are mechanically combined and the locos are single-manned, though no automatic controls are used for the firing system.

Results to date show fuel consumption to be very low, while nearly perfect combustion has been achieved; in fact exhaust emission is cleaner than that of a diesel loco.

Back home in Britain, much development is taking place at present, which should go a long way towards countering the effects of problematic firebox layouts such as 'marine' type boilers, and indeed many other locomotives that inherently do not lend themselves to the adoption of systems which are currently commercially available. Oil firing has an established place in steam preservation and where circumstances make it a necessary or preferable alternative to coal firing, our railways deserve the best possible system.

|

The

Arn Jung Graf Schwerin-Lowitz as an oil burner, at Pant station, BMR,

8 August 1993.© Neil Thompson |

Note: This article first appeared in Railway World, May 1994. Reproduced with the consent of the author.