Welshpool & Llanfair - Improving the Fleet

David Moseley reports on the front end redesign work carried out at Llanfair Caereinion

Modern steam technology has been little used in Britain to any extent, so in certain areas introducing it can bring radical improvements, most noticeably in the fields of combustion and draughting.

The basic aim of any front end is to get the most vacuum for the least amount of cylinder back pressure. This is best achieved by mixing exhaust and combustion gases, rather than using just the force of moving fluids. For many years front end design was by rule of thumb, moving on to increasingly-experienced guesswork. But with the technology of the past quarter-century, it is largely possible to predict and calculate the desired effect.

The steam fleet of the Welshpool & Llanfair presents this story in microcosm. Recent considerable improvements have been made in the light of experience. Ironically, the real spur to tackling the matter came from a loco no longer on the line!

Back in the mid-1970s, the articulated locomotive Monarch covered some of the line's scheduled services. In fact in 1976 it was the mainstay of the loco fleet. Occasionally good, most of its career at the W&L could however only be described as mediocre. There were a number of reasons for this:

|

Monarch

at work: The Bagnall is seen on the sharp climb between Sylfaen and Castle

Caereinion on 3 June 1978, during its short lived active career on the

line. © Brian Morrison |

After a brief spell in service the loco was sidelined in 1978, awaiting a retube and the fitting of vacuum brakes. However in the mid-1980s it was decided to sell the loco, as its suitability for operating regularly and reliably over the newly-extended railway was called into account. Various people and organisations came to view Monarch and eventually an offer was made by two members of the Ffestiniog, which was accepted, the loco departing for Minffordd Yard in 1992. At present it is stripped and dismantled for conversion to 2ft gauge, full overhaul and oil-firing.

While the engine was being stripped into its component parts, Shaun McMahon of the Vale of Rheidol wrote to the W&L, asking for details of its history while operating, and of any problems which had occurred. Shaun and his colleague Nigel Day of the Snowdon Mountain Railway had previously worked together studying steam locomotive performance, combustion systems and front end design in particular. Shaun had worked on the Ffestiniog's Linda while it was being used as a test bed for various modifications during the mid-1980s.

Shaun and Nigel researched the problems described with Monarch and came up with various solutions, not the least of which was to design a completely new oil-firing system and allied exhaust system, in order to reach the highest possible level of efficiency.

When Monarch first arrived at Llanfair it had a spark arrestor chimney fitted from its days in Bowaters Paper Mill. After arrival some work was done, including the fitting of a replacement chimney, and what is now apparent is that some of the steaming problems could have been cured by a correctly-sized chimney or liner. Put simply, the used steam passed so easily through the chimney that little or no vacuum was created in the smokebox and therefore no draught pull on the fire. Little wonder then that even without the spark arrestor the loco was never prone to setting the countryside alight!

Following the Monarch discussions, the offer was made by Nigel Day to investigate and offer a remedy to, any problems we had with steaming or performance of any other locos in the fleet.

In the early part of the 1993 season we were experiencing problems with the Hunslet 2-6-2T No 14, which had a tendency to throw fire and also gave the impression of being rather heavy on coal. (Since we have been measuring coal consumption, it is interesting to note that while not as economical as the superheated No 10, the loco is far superior to No 2, of which more anon.)

As a result, Nigel and Shaun spent one of the very few hot days last summer testing No 14 extensively, having fitted it up with gear to measure smokebox draught, back pressure in the cylinders and temperatures of the smokebox gasses and exhaust steam. The steaming rate was carefully monitored against output.

|

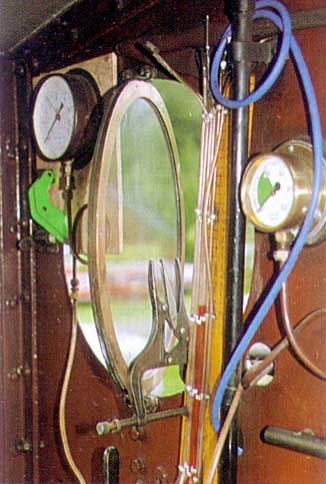

Inside

No 85's cab on the test runs: the cylinder back-pressure gauge and smokebox

vacuum gauge are clamped to the cab-sheet. © Shaun McMahon |

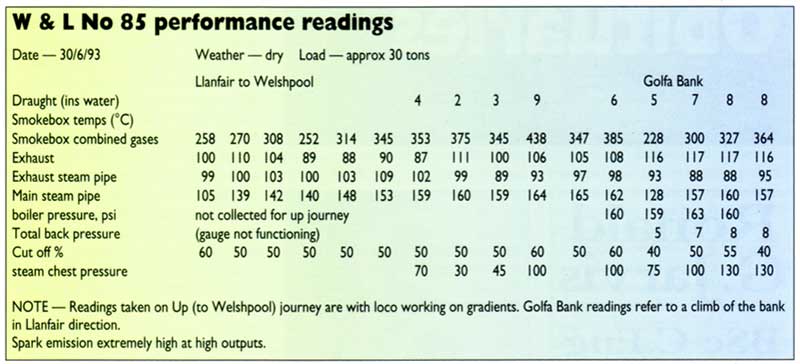

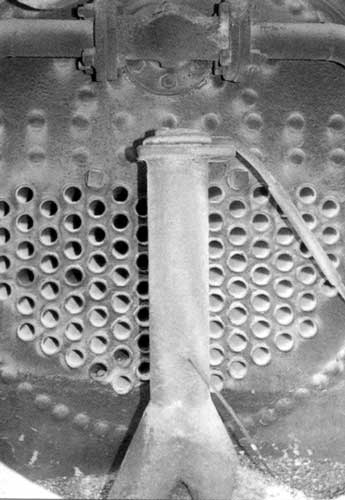

The table gives some indication of the problem. What is does not show is the large amount of spark emission, which caused two large lineside fires that resulted in the Fire Brigade being called out and the loco being banned from further trains until it was modified or the weather changed to rainy!

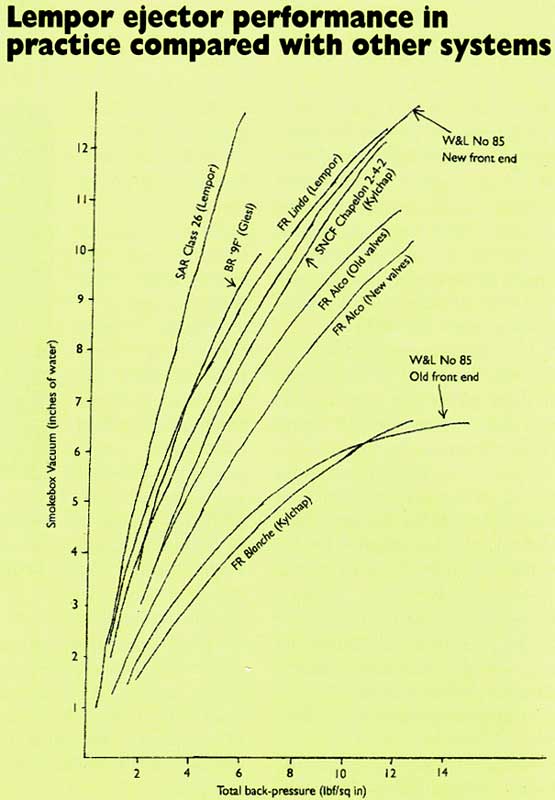

By mid-August 1993 Shaun and Nigel had produced a report and a redesign of the front end arrangement. Our own volunteer workshop staff built the new blastpipe with a four-nozzle De Laval top, and a two-part corrective liner was obtained and fitted inside the existing chimney. At the same time a new blower was fitted, with convergent/divergent nozzles.

At this stage it is worth considering the background to the modifications then made.

Chronologically the development of front end design was initially through Andre Chapelon's work and the Kylchap system in the 1930s, followed by the Lemaitre and its derivatives by Bulleid. Perhaps the most obvious front end redesign was that of Dr Giesl. Unfairly maligned at first, the design saw reasonable use in other countries and has been tried out here latterly, with good effect, on the preserved 'West Country' 34092 City of Wells.

|

The most efficient, simplest evolutionary designs of modern front end arrangement are the Kylpor, Lempor and Lemprex systems developed by L.D. Porta and his associates. It is these systems that are being used on the W&L. In terms of narrow gauge locomotive performance and improvements, the Ffestiniog led the way in a series of experiments using the ex-Penrhyn Linda. This loco was the testbed for oil-firing in the 1970s and in the mid-1980s was modified again to burn coal on the Gas Producer Combustion System. At the same time the front end was modified to the Lempor system, with a four-nozzle blastpipe top and a tapered chimney replacing the original Hunslet-designed article. The reason for the front end redesign was to produce a reactive exhaust which drew evenly across the firebed and also to produce proportional high levels of turbulence, as primary air intake is limited to very low levels in the Gas Producer system. Combustion of the gases takes place above the firebed, using much higher levels than normal of secondary . While the converted Linda worked reasonably satisfactorily, the reduction in oil prices (the increase in which had led to the Gas Producer experimentation) meant that it was more feasible to return the loco to oil firing. The front end modifications remained and now provide an interesting comparison with the unaltered Blanche in terms of total back pressure against smokebox vacuum, as shown on the graph. |

The W&L's modified No 14 is a little way behind Linda but a considerable technical improvement over its previous performance.

|

The

improved No 14 attacks the start of Golfa Bank as it leaves Raven Square

on 17 July 1994. © Peter Johnson |

Once the modifications were completed, No 14 was tested and returned to traffic. The difference in performance was immediately apparent. In its unmodified state the loco was normally restricted to a maximum load of five 'coach units' (30 tons) up the 1 in 29 out of Welshpool but with the modifications it easily managed six units with a reduction of around 5% of coal consumption. Regular crews were reporting reduced coal consumption of around 10% on normal trains. The cost of the materials used in the modifications was recovered within 30 running days.

Ironically the spark emission still remained high and the fitting of a fine mesh spark arrester was to follow in the early part of the 1994 season.

Alterations in the method of firing the loco also help in reducing spark emission. In traditional firing practice all the combustion air is admitted below the grate. This causes the lighter (and some of the heavier) particles to be drawn through the tubes and ejected, particularly at times of hard working. To reduce these emissions, the primary air is kept to a minimum (about 30% is sufficient to prevent the firebed from going dead) and secondary air from the firehole door burns the liberated gases given off from the firebed. Using this technique, clinker is less likely to form. The front damper should be kept shut at all times and a minimum amount of back damper used. Too much air through the firebed will cool the combustion gases and reduce the steam output.

No 14 ran for the latter part of the 1993 season in this modified state.

|

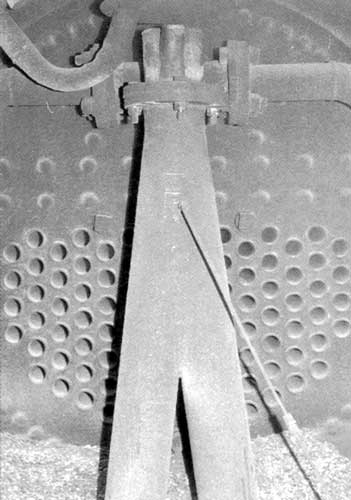

The

old and new smokebox arrangements in No 14/85: note the streamlined exhaust

pipes, Lempor exhaust manifold and chimney petticoat/mixing chamber in

the new installation. © Shaun McMahon |

Following the success of their design for No 14, Shaun and Nigel now turned their attention to No 2 The Countess. Never a particularly good steamer, it was noticeably heavier on fuel than the other locomotives and was therefore considered an ideal candidate for conversion. Immediately after the season ended Nigel produced drawings and the modified front end was made.

Using the existing blastpipe base, the top was modified to a four-nozzle pattern similar in external appearance to No 14's but differing internally, as all exhaust systems have to be tailored to the gas-free area of the boiler, which can be calculated only following a proper gas analysis survey. Also a liner was fitted to the chimney, reducing the choke size. A new blower ring and rerouted ejector exhaust were also provided.

It was not possible to test the locomotive immediately after construction, owing to other ongoing work, most notably its wheels being away at the Ffestiniog for reprofling. Problems with 0-8-0T No 10 Sir Drefaldwyn then led to The Countess re-entering service earlier than expected and it ran for the first time in its modified state a week before Easter 1994. Its first run showed that all was not well and further investigation was required.

It soon became apparent that the ejector exhaust was obstructing one of the nozzles and that there was an alignment problem with the blastpipe itself. Once these minor problems were rectified the loco was tested again and the difference in its performance was outstanding.

The Countess is still not as efficient as No 14 in terms of coal and water consumption, part of which can be attributed to the ex-GWR vacuum ejector used, and further improvements may be gained from modifications to the valve gear. However, its improvement to date has led certain people to eat their words about the boilers of the two original engines being at the limit of their steaming capacity.

|

No

10 drifts into Llanfair station (also much improved!) on 4 September,

during the Enthusiasts' Gala Weekend. © Peter Johnson |

During the winter of 1993/94 the Austrian 0-8-0T No 10 also received front end attention, with new exhaust pipes and a modified Lempor blastpipe top. It was due to enter service in the early part of the season but mechanical problems delayed its appearance. Its eventual usage will make interesting comparisons with the other two converted locos, bearing in mind that as a superheated engine it was far more efficient in terms of coal and water consumption anyway.

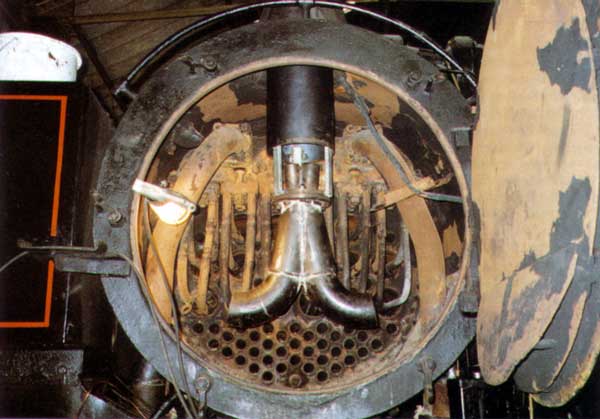

|

No

10's new front end takes shape. The new exhaust pipes (yet to be connected),

blastpipe, nozzles and chimney liner are in place. © P. Rowe |

Looking ahead, the eventual overhaul of the W&L's No 15 will be a chance to put some of the lessons learned from the previous conversions to good effect. A large 2-6-2T, one of a pair built by Tubize in 1948, the possibility of converting it to run on the Gas Producer Combustion System has not been overlooked and as the loco needs a replacement firebox, any necessary alterations should be easily incorporated.

Basically a modern design, the Tubize is likely to be an easy engine to maintain. Its component parts all appear to be in reasonable order, with the exception of the boiler and some platework.

|

Monarch

and the Tubize 2-6-2T stored together at Llanfair in 1985. The view gives

a good idea of the size of the next loco to join the active fleet. ©

Peter Johnson |

Presently

completely dismantled, the loco's boiler has recently been surveyed to assess

the costs involved in its repair. If funds are then forthcoming, the boiler

may be sent away for overhaul in April 1995, with a view to completion and return

to the railway that autumn and the loco's entry into service at Easter 1996.

Close

Window