Oil Fring & Lempor Exhaust Systems

Oil Firing

A lot of research and experimentation was undertaken to come up with the current design of Lempor oil burner. The system utilises a round burner which ejects a flat disc of fuel. Output is proportional to the burner diameter. Whilst the details of the system are confidential having seen it I know it is very simple and involves only a few components. This elegant simplicity has been rewarded by superb performance. To date Welsh Highland Railway NGG16 Garratt NG138, in which the system was initially proved, and SMR No.4 have carried the burner. Further installations are under discussion.

Fuel savings in the order of 25-30% have been achieved in day to day service. Nigel, however, is not happy to sit back now. Further research and development is in hand to meet future demands.

Fellow engineer Shaun McMahon, in an e-mail to the webmaster, said of Nigel's system:

"...I travelled on board (No.4) in August 2000. As I have stated before to many people, it was the very BEST I have seen an oil fired engine perform on a railway to date..."

|

One

of the burner experiments. Note the loops of pipework towards the rear

of the flames. These superheat the atomising steam. Superheat is an important

improvement for all oil firing systems. © Nigel A. H. Day |

|

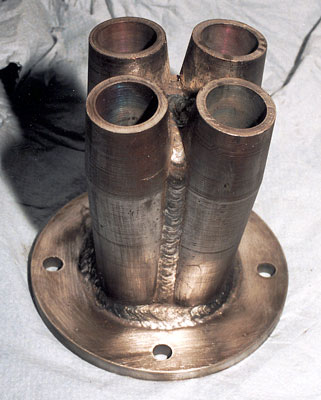

This

is a burner of the type designed by Nigel. The burner is securely fixed

to the firepan with bolts through the holes in the round base. Below the

base plate are the feeds for oil and superheated atomising steam. The

atomised fuel is ejected at the top of the burner. © Nigel A. H.

Day |

Lempor Exhausts

|

A

general arrangement diagram of a Lempor exhaust arrangement. Fundamentally

this is what Nigel's systems are like but normally hidden within the traditional

chimney. Source: Porta, L.D. 'Theory of the Lempor Ejector as Applied to Produce Draught in Steam Locomotives' |

Nigel's Lempor nozzles are made by turning steel bar. This is unusual as most in the past, such as those in South Africa, were fabricated from plate. The nozzles have an excellent life span with many in use after ten years with no sign of char cutting etc. Plate nozzles last nowhere near this amount of time.

|

The

first part of the construction process involves turning the internal and

external dimensions of the steel bar to the specified dimensions.©

Nigel A. H. Day |

|

The

finished result will look something like this one. Obviously a good few

stages have been missed out in the photographs ! © Nigel A. H. Day |