141R 1199

141R 1199 was built by Baldwin of Philadelphia, Pennsylvania, USA, in 1947 and was shipped to France in the same year. The idea behind the building 1340 141Rs was to ensure SNCF had enough working, reliable and powerful motive power to haul trains after the end of World War II and as the country was returned to normal. At this time much French motive power was either out of action or in need of heavy overhaul as a consequence of the war.

141R 1199 at Montargis. 05 May 2007

141R Vital Statistics |

|

| Driven Wheel Diameter | 5'5" (1651mm) |

| Cylinder Dimensions (2) | 23 5/8" (597mm) x 28" (711mm) |

| Maximum Permitted Speed | 100kph (current and when in regular service) |

| Boiler Pressure | 220psi (15bar) |

| Grate Area | 55.5 sq. feet (5.16 sq. metres) |

| Heating Surface | 2649 sq. feet (246 sq. meters) |

| Exhaust System | Kylchap |

| Maximum driven axle load | 20t |

| Weight in working order | 114t |

| Water Capacity | 6600 gallons (30000 litres) |

| Fuel Oil Capacity | 5005 gallons (22750 litres) |

| Water Treatment | TIA, from new |

The 141Rs are, not surprisingly, an excellent example of mid-1940 North American locomotive practice built down to the French loading gauge. In the case of No.1199 it is equipped with a cast steel bed - that is the entire frame structure, cylinders and smokebox saddle is a one piece casting. In total 199 141Rs were built in this way. These machines were the first in Europe to be so equipped. The remainder had more traditional bar frames with each cylinder casting also being made up with half of the smokebox saddle - very familiar to anyone knowing the locomotives GWR Churchward and Collett two cylinder locomotives.

141R 1199 is serviced at Montargis. 05 May 2007

The axleboxes were fitted with Franklin type spring loaded wedges which are well known as devices for taking up wear in the axleboxes and reducing the effect of "shocks" leading to improved bearing life and a better riding locomotive. The engine and tender are coupled together in such a manner that there is very little movement between the two. The effect of this is to smooth out the fore and aft motion associated with two cylinder locomotives, especially ones with big cylinders like the 141Rs. To achieve this result a Franklin Radial Buffer was used. Various types of this buffer were used over the years, details of the type in general can be found here.

|

The castings on the loco - including the cast steel bed - were made by the General Steel Castings Corporation of Eddystone, Pennsylvania. |

Early 141Rs came with traditional spoked wheels but later machines, including No.1199 came with Boxpok type wheels. In later years it was not unusual to see 141Rs operating with a mix of wheel types! Certain locos came with roller bearings on all axles, others just on the driven axles and the initial machines with no roller bearings at all.

The 141Rs are fitted, as would be expected, with two methods for filling the boiler whilst in steam. One of these is a non-lifting injector controlled from one lever to the left of the fireman's seat. The other is a Worthington type feedwater heater and associated cold and hot water pumps.

The locomotive is equipped with a cross compound type of air brake pump. From new they also came with power reverse - then new to France. In the early 1960s, as 141Rs started to be withdrawn, the power reverse cylinders were transferred to the 241P fleet.

No.1199 is one of the 141Rs set up to burn oil. The oil burnt is a heavy oil, referred to as Mazout. Due to it's nature the oil has to be heated to around 75 or 80°C prior to burning in the firebox, which is done through a steam heating coil in the tender. However when not in steam the oil is heated by steam provided from a generator in a vehicle which accompanies the locomotive. The hot oil is sprayed into the firebox at which point it mixes with atomising steam, in other words it is externally atomised. Whilst such external atomisation was once popular it has since been shown internal atomisation (that is atomisation prior to the fuel entering the firebox) is better. However with this type of fuel proper atomisation in locomotive applications is very hard which goes some way to explain the amount of smoke such locomotive produced and why the tubes need to be sanded every 150km or so of use. In coal burning form 141Rs have a mechanical stoker.

The locomotives are quoted as carrying enough water to run for 150km (93 miles) without taking water and 650km (404 miles) without taking on fuel oil. No mention is made of the safety margin contained within these figures.

Initial locos were fitted with the less than fantastic, but very typical, plain nozzle and single chimney common to North American practice at that time. The blast tip nozzle was 197cm2. However the French already had something much better - Chapelon's Kylchap exhaust. This system was already well proven in France on a range of different machines. The version designed for the 141Rs had a blast tip area of 229 cm2.

When scientifically tested locomotive No.469, then still equipped with the original North American blast pipe, was shown capable of producing a maximum continuous output of 2633dbhp at 80kph. No.874, equipped with the single Kylchap arrangement, was able to sustain 2928dbhp at 80kph - quite a substantial increase in power. Coal consumption was also reduced per horsepower produced.

When scientifically tested locomotive No.469, then still equipped with the original North American blast pipe, was shown capable of producing a maximum continuous output of 2633dbhp at 80kph. No.874, equipped with the single Kylchap arrangement, was able to sustain 2928dbhp at 80kph - quite a substantial increase in power. Coal consumption was also reduced per horsepower produced.

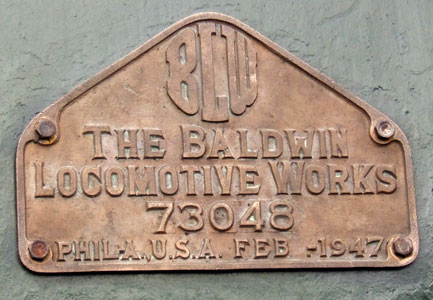

No.1199, works number 73048, spent its entire operating life based at Le Mans. It was shedded there from 17 July 1947 through to withdrawal on 25 August 1971. In that time it covered 1,627,474km (1,011,265 miles).

Following withdrawal the locomotive was selected to be returned to the USA for exhibition in San Diego. However problems with transport saw the plan fall through and the locomotive remained in France.

In 1992 No.1199 was moved to Nantes at the request of some of the local railwaymen who wished to restore the loco. By 1995 the Association was formalised and an agreement signed with the loco owners, SNCF, regarding its operation. Thus in the care of the 'Association Loco Vapeur R1199' the loco was overhauled and returned to mainline service. The loco is now based in Nantes and generally runs excursions from there to points nearby.

'Le Mistral' was the furthest from home the locomotive had traveled since its return to service and represented quite a commitment from the Association. Certainly from a passenger's perspective it appears as if everything went very well and it is to be hoped this is not the last time the loco ventures away from its normal home territory. 141R 1199 comes highly recommended!

The official website for No.1199, including a list of forthcoming railtours, can be found at http://r2nantes.free.fr For more details on the 141R class the following books are recommended, with the second being in French:

|

|